When considering a new set of wheels for your vehicle, car enthusiasts want a set of wheels that stand out. Often, aftermarket alloy wheels are the solution to the standard stock wheel and are available in an array of finishes and designs. While upgrading the exterior appearance might satisfy most, many consumers wanting to enhance the look of their vehicle, are probably interested in the performance of their vehicle as well. Choosing lighter wheels is a great starting point.

Alloy Wheels

The popularity of alloy wheels has dramatically increased since the 1980’s. Alloy wheels are considered an upgrade from the standard steel wheel and consumers have watched as production practices have evolved. The three popular construction methods for creating a lightweight wheel are casting, flow forming, and forging. Cast wheels are often inexpensive and offer the most style options. Flow-form constructed wheels are both lighter and stronger than cast wheels but will cost a bit more out of pocket. The most expensive will be forged wheels, due to the intricacy of the manufacturing process.

Casting – Aftermarket wheels are most commonly cast using a blend of aluminum and nickel. The material is heated to high temperatures, melted into a molten liquid, poured into a mold, and cooled, creating a lightweight and durable wheel. The wheel is then cleaned up and drilled to specs and off to be coated.

Flow Form – Flow-formed wheels are cast like any other wheel. However, once cast, the wheel is reheated to a high temperature, and the barrel of the wheel is then pulled down and widened by spinning discs. This ultimately strengthens the aluminum while using less material to form the final shape of the wheel, compared to a fully cast wheel.

Forged – By far the most intricate and expensive process, forged wheels are constructed using a solid piece of aluminum called a mono-block. The mono-block is heated and pressurized to form the shape of the wheel. Once formed, the wheel is lathed and then precisely milled using a CNC machine to remove access material. This creates an incredibly lightweight wheel that is about 3 times the strength compared to a standard cast wheel.

Does a lighter wheel affect performance?

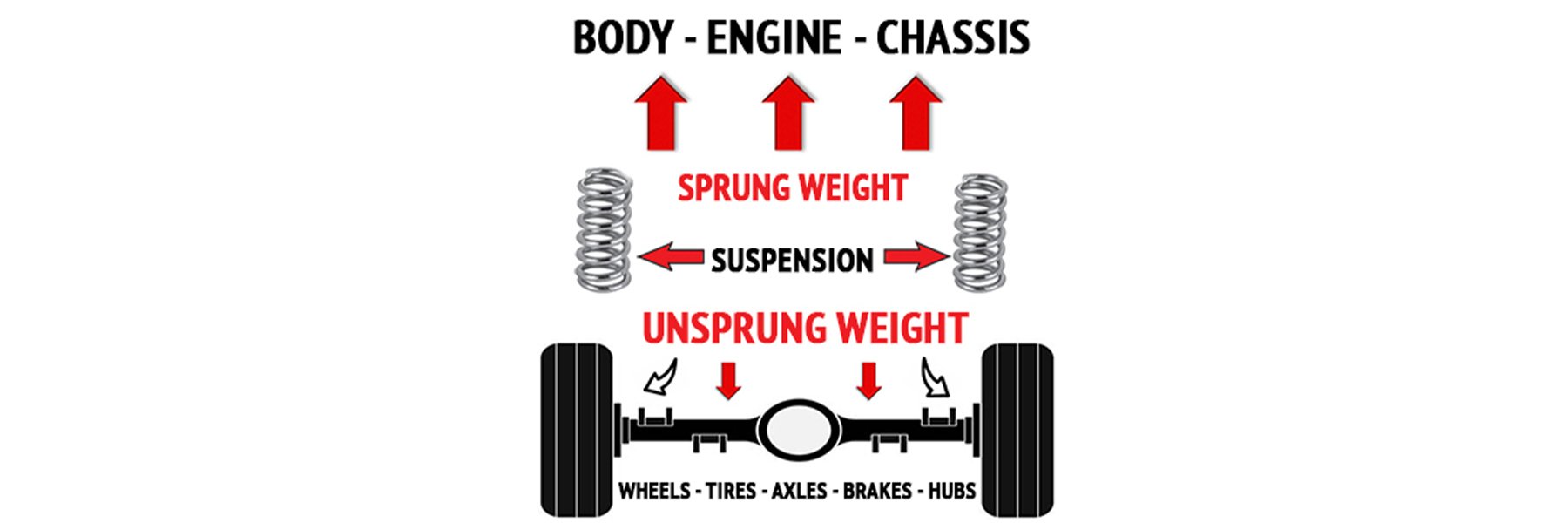

Your wheels and tires are a part of the unsprung weight of the vehicle. This includes every component that is unsupported by the suspension system (axles, braking system, etc.) Unsprung weight affects the car’s handling, and ability to accelerate and brake. With wheels that weigh less, less strain is placed on the suspension when steering, thus allowing the suspension to rebound faster and deliver an overall smoother ride. The rotational weight of the vehicle (tires, wheels, shock absorbers) with lighter wheels requires less energy to operate. By having less support, the vehicle will both accelerate and stop more quickly. Additionally, with less weight, your vehicle will get better MPG on the road.

Decisions

At the end of the day, lighter wheels are certainly beneficial to your vehicle’s performance. By replacing your stock wheel setup with great quality, lightweight alloy wheels, you are reducing a portion of the unsprung weight of the vehicle which will ultimately increase the overall performance. Lighter-weight wheels are an option to consider while upgrading other performance-enhancing components.