Strength, Lightweight, and More Options

When determining what manufacturing process to use for our line of Factory Reproductions Wheels, three important factors were considered: weight, strength, and options. That’s when the idea of Flow Formed manufacturing settled in.

It was also imperative that we create a wheel line that offers more options than the standard OEM width and offsets, allowing for personal expression of style. All of these considerations pointed us in the direction of Flow Formed manufacturing for our Factory Reproductions wheels.

Flow Formed Benefits

Highly Durable: Because of the flow formed process, the mechanical properties of the aluminum now have improved grain structure and increased strength compared to a traditional cast wheel.

Light Weight: With increased material strength, the rim barrel is spun thinner than a traditional cast wheel, reducing wheel weight. This results in improved performance and ride quality.

Increased Options: Multiple forming programs are written to allow for more widths and offsets than the traditional cast wheel.

Hybrid Cast and Forged Process

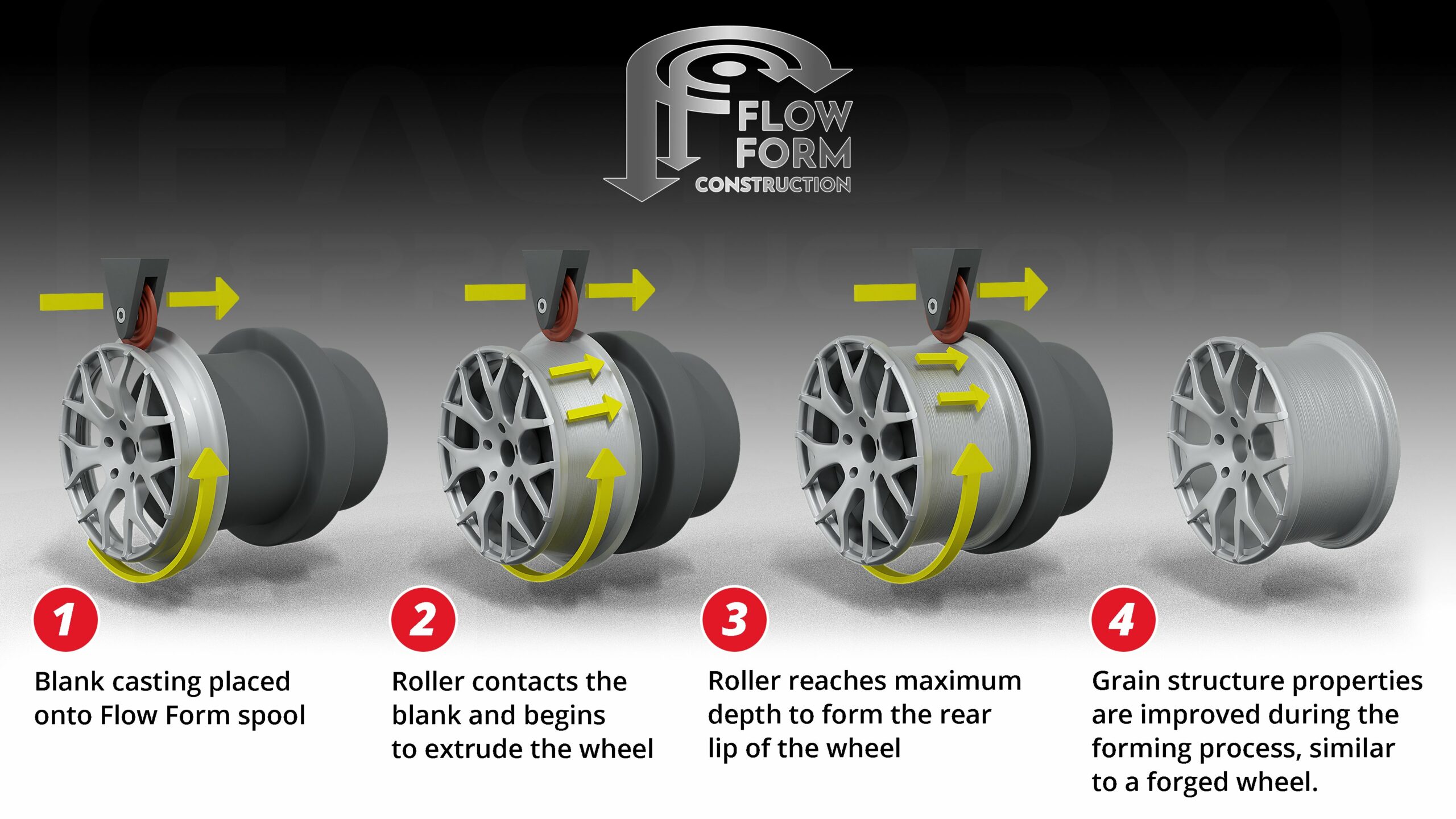

The flow formed process is essentially a hybrid process of cast and forged wheels. With flow-formed manufacturing, wheel performance is improved by increasing wheel strength and reducing wheel weight.

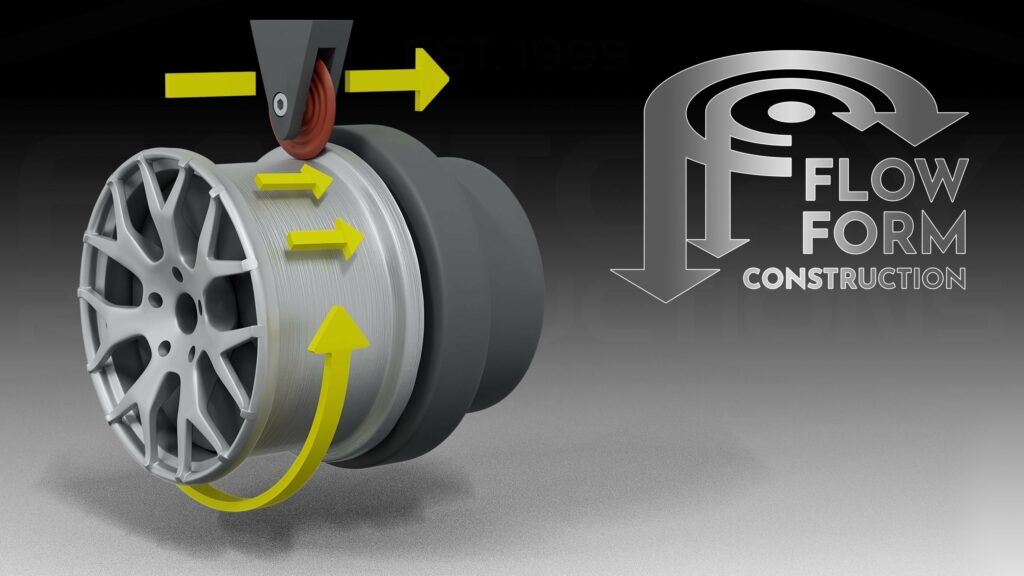

The Flow Formed Process

Each Factory Reproductions Wheel is built from A356 aluminum alloy. This material is known for its strength and favorable casting properties.

- Initial Casting: The procedure begins like a cast wheel where aluminum ingot, magnesium, titanium, and silicon are heated to liquid form, filtered, degassed, and inspected. The liquified aluminum is poured into the casting machine’s crucible to be pressurized into the high-temperature steel mold.

- Measurement: Once solid, the casting is removed from the mold, bathed in water, and general measurements are taken to confirm the correct wheel size.

- Checkpoint: One of the distinguishing characteristics of a flow formed casting shows up at this point. A short-rim barrel skirt appears as it has not yet been formed into the full rim width.

- Preparation: To prepare for the Flow Formed process, the wheels are conveyed through a preheated oven and placed on a preheated mandrel which is shaped in the final rim barrel profile.

- Flow Formed Process: With multiple passes, forming rollers slowly squeeze and stretch the thick aluminum skirt material resulting in the final rim barrel shape. This forming process produces an extremely consistent and uniform barrel thickness which absorbs impact energy better than one that is fully cast.

- Strength: The wheels are then bathed in water once more and taken to a heat treatment stage that locks in the proper hardness levels.

- Quality Control: Specific quality control checks and rigorous wheel tests are performed to ensure strength, durability, and overall quality.

Once the wheels have passed through these thorough inspections, they can officially be considered flow formed Wheels.

Your Factory Reproductions Wheels Are Ready to Make a Statement

Because Factory Reproductions wheels have been manufactured using the flow formed process, you can be certain that they are of the highest quality. These lightweight, durable wheels will allow you to take to the streets in style with added strength so you never have to worry about missing a beat.